Project Profile

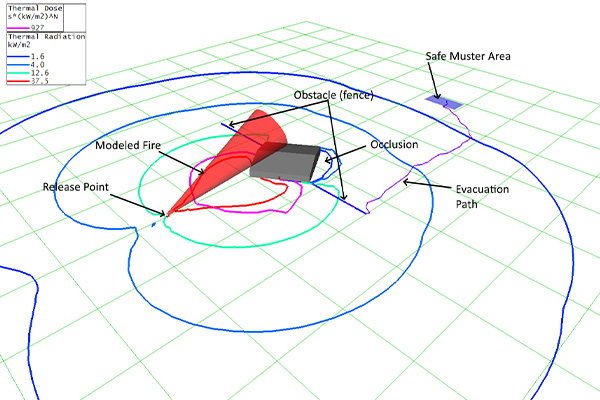

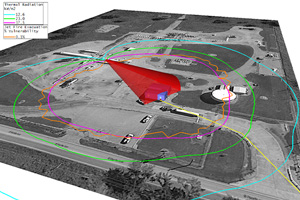

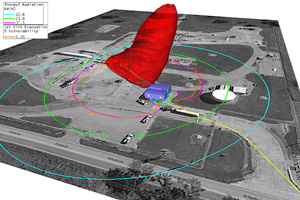

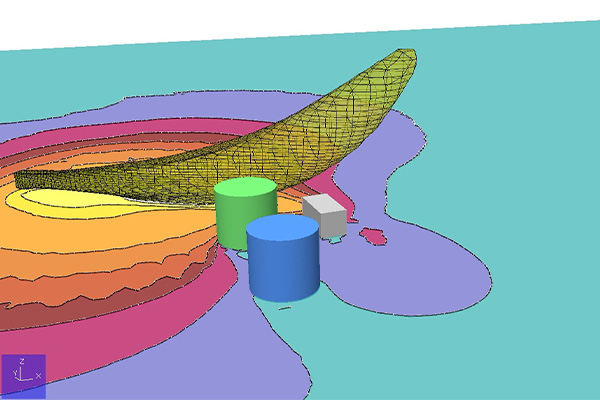

Detailed Fire Modeling of Jet and Pool Fires

Learn how our Extreme Loads and Structural Risk engineering team uses advanced analysis techniques to model fires and better quantify hazards to personnel.

Project Objectives

#1

Facility siting services address explosion, fire and toxic hazards to buildings and structures used in oil, gas and chemical operations.

#2

We apply advanced analysis techniques to model fires and better quantify hazards to personnel.

#3

Our Detailed Fire Modeling provides the most accurate prediction of fire consequences, allowing for a better assessment of thermal hazards during evacuation.

Project Overview

Facility Siting addresses explosion, fire, and toxic hazards to occupied buildings. This project profile describes how our Extreme Loads and Structural Risk engineering division addresses prediction of pool and jet fire consequences.

Evaluating fire, toxic and explosion hazard consequences is required by regulatory agencies to demonstrate worker protection and public exposure.

Detailed Fire Modeling provides the most realistic simulation of jet and pool fire hazards. Applying CFD modeling for fire scenarios also provides better consequence prediction than traditional approaches used in support of Facility Siting studies and has helped many of our clients eliminate expensive remediation options.

ABS Group uses Detailed Fire Modeling to assist with incident investigations and in thermal-structural Finite Element Analysis (FEA) to understand the effects from an extreme loading environment on the behavior of buildings/structures of interest.

Client Needs

- Assess and predict thermal hazards at facility sites using advanced modeling techniques for better prediction of fire consequences

- Understand unique risk and practical measures for risk reduction and regulatory compliance

- Safeguard personnel by maintaining the integrity of critical assets and promoting process safety management through facility siting

Value Delivered

ABS Group's Extreme Loads and Structural Risk engineers help clients clearly understand facility siting risks and quantify consequences. Our knowledge and experience with a range of hazard analysis tools, including Detailed Fire Modeling, allows us to select and apply the most appropriate techniques for each situation. Our Facility Siting services cover a wide range of explosion, fire and toxic release hazards that pose a threat to refining, petrochemical and specialty chemical process installations.

Our engineering and risk consulting teams work diligently with clients to develop and implement the practical measures needed for risk reduction and regulatory compliance.