Insight

A Short List of Best Practices for Combined Heat and Power Projects

ABS Group Safety, Risk and Compliance Services

Combined heat and power (CHP) projects promise many benefits to a wide array of large and small energy users, and CHP has a long history of adoption and success in many industries. Because their primary business usually has nothing to do with electricity generation and utility operations, many energy users are not fully equipped to handle all of the development tasks and challenges of a CHP project.

To help new industrial and commercial energy users who are considering implementing CHP at their facilities, we have identified a short list of best practices to consider at each stage of development and project execution to mitigate risks and manage project success.

1. Build CHP Projects on a Strong Foundation

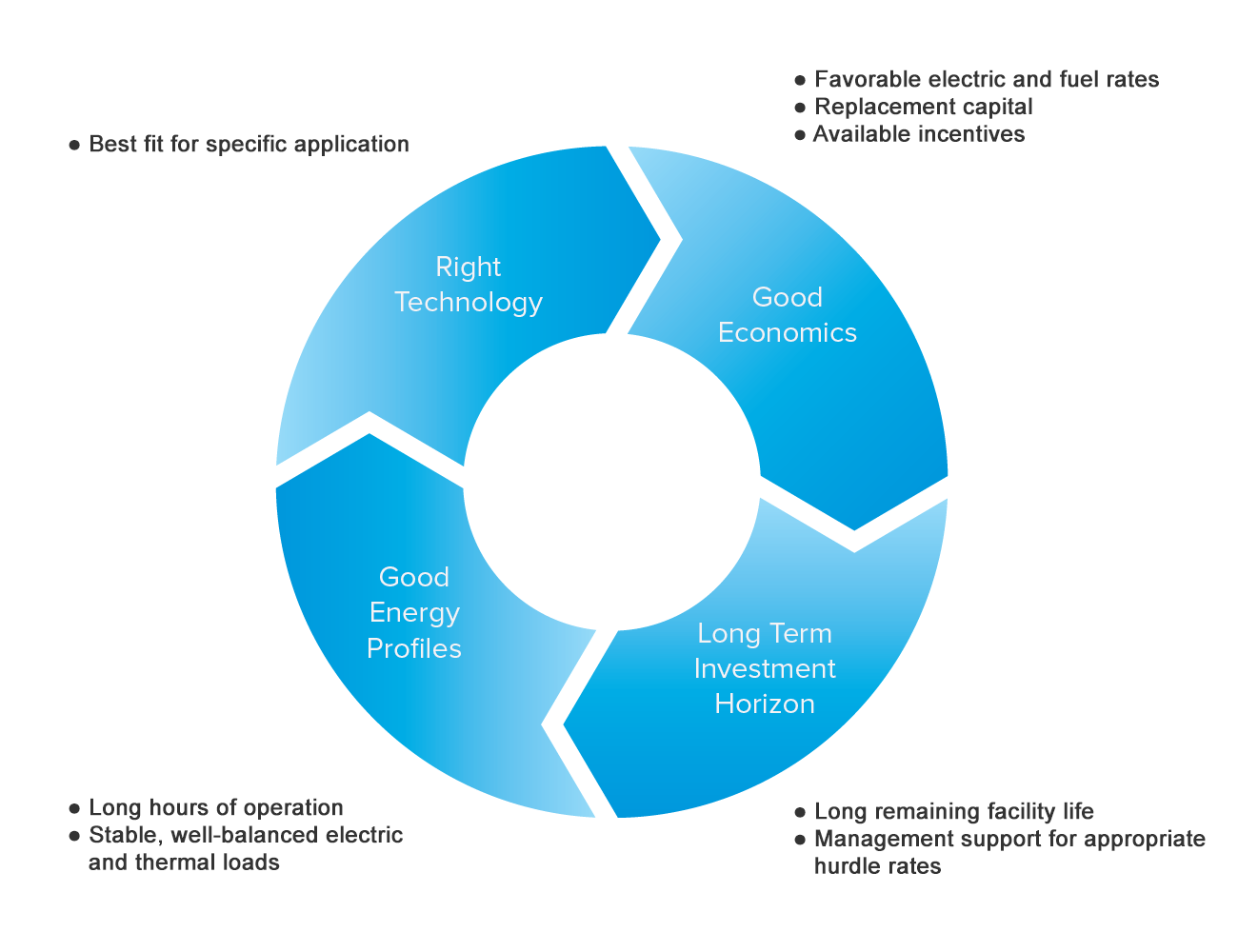

Successful CHP projects are built on strong technical and economic foundations as represented in the chart below.

Projects that are based on all of these foundational elements are likely to succeed. Even if some of these characteristics are not as strong as others, specific projects can still be successful with careful analysis and development.

2. Choose the Right Technology for the Project

These factors all impact the technology selection for a CHP project, so the following are important considerations to keep in mind:

- Output and system sizing – specifying the largest system technically possible may not provide the highest return on investment. Generally, the focus should be to match the thermal loads as a priority in setting the overall CHP system capacity. This approach usually offers the most efficiency and return on investment.

- Heat rate – since useful heat is an output of the CHP system, the maximum efficiency power generation equipment may not equate to the most overall CHP cycle efficiency and in fact may penalize the project with higher costs and lower economic value

- Load following – a properly sized system should run at full output most of the time, so ramping and load following capability may not be the most important characteristic of the equipment selection

- Grid isolated operation – designing an onsite generation system to operate in an islanded mode during grid outages can add value to the project by enhancing site reliability, but brings complexity and cost, and may not be utilized that often, so the costs, risks and benefits should be carefully considered.

3. Manage Project Development Process for Success

The project development process is best tackled in phases with staged investments and increasing levels of detail in engineering and specification as the project becomes clarified. This approach avoids false starts by uncovering key risks and threshold issues early in the development process. The benefits of the project then become clearer and better defined over the course of the development process. The following are some basic milestones and activities to guide a more detailed development plan:

First Look

- Factored cost estimates

- Basic system sizing assumptions

- Basic system operating profiles

- Preliminary annual energy savings and operating costs

Feasibility Study

- Budgetary cost estimates

- Hourly facility load profiles

- Basic design and siting decisions, including system sizing

- Main equipment selection

- Hourly energy and financial model with all rate information

Financial Investment Decision (FID)

- Detailed design basis with FEED

- Engineering based cost estimates with uncertainty analysis

- Hourly energy and financial model with time of use rates

- Energy price forecasts

- ROI risk analysis

4. Gain Management Support, Present Long-term Value

When it is time to present a project to management for funding approval, there are a number of important factors to take into account. The most fundamental is to understand the financial metric, such as a return on investment hurdle rate, that the project will need to meet for approval. CHP projects are by their nature long lived assets which add long term value to facilities when they are implemented and maintained properly. They should therefore be judged on par with other long term, facility expansion or production capital projects. Too often CHP projects get lumped into smaller "energy" projects with very short payback thresholds imposed by default. This can screen out otherwise excellent long term projects.

One special case that often arises in commercial and industrial CHP projects is a third party design-build-own-operate-maintain (DBOOM) structure. This often sounds like an attractive deal, especially to facility teams who believe it can be a source of financing outside of the internal capital approval process. However, these structures bring complexity and risk, and sometimes cannot achieve the financial result that owners are seeking – namely off-balance-sheet treatment of the investment. There are cases where DBOOM structures may be a good fit, but it is important to analyze a project’s components separately with regard to design, construction, financing, operation and maintenance. It is possible to achieve goals of outsourcing operation and maintenance responsibility without bundling these with the financing and EPC of the project.

5. Continuously Evaluate Risk and Uncertainty for Project Assurance

As a project matures in the development process, it is important to continually analyze project uncertainties and risks. To this end, it may be beneficial to conduct a probabilistic analysis, which characterizes the uncertainties of key input variables based on historical or market-based data and forecasts the return on investment under thousands of simulated scenarios through a Monte Carlo analysis.

This approach can help a project team present the result as a probability in the form of a statement such as, "This project has an X% chance of earning a Y% internal rate of return or better." In this way, management can judge the risks and certainty of a proposed project in a much more informed way than how static models with fixed assumptions can provide. These models can be updated as the project development matures to keep a current view of risks and uncertainties.

6. Match Project Execution Strategy to Organizational Situation

While heading toward project execution, consider the following readiness questions:

- How much internal staff does an owner have to support project execution?

- How much risk is an owner willing to take directly on equipment performance and construction?

- What form of EPC structure and execution strategy is best for your project?

- Would a collaborative approach, such as using an open book EPC development and pricing process, followed by a closed book execution, help the development and execution process for your project?

7. Start with the End in Mind – Enterprise Asset Management

Finally, the value of a CHP project will only be realized if a well-designed, comprehensive Enterprise Asset Management plan has been implemented for this type of asset. Many facilities may not have managed a power generation plant previously, and so maintenance procedures, data collection, computerized maintenance management systems (CMMS), reliability procedures and safety procedures will all need to be designed and implemented for the plant. Starting early and getting expert input as to these aspects of operating and maintaining a CHP plant will set the stage for long term operational excellence of the total asset.

Bottom Line Drivers

Return on Investment, Lower Risk and Environmental Benefits

There are a number of good reasons to implement CHP technologies, but the first and foremost driver for these systems in an industrial or commercial business setting is to earn a compensatory return on investment that is comparable to other long term capital investments being made in the business. Secondary benefits may include improving environmental performance through dramatic increases in efficiency, improving reliability or providing back up generation at site, and managing long term energy risks more effectively.

Ultimately, CHP projects can deliver significant value for facilities that choose to develop and implement them. By focusing on best practices from the start of project development, to execution and on to long-term operation and maintenance, new owners of CHP systems can mitigate risks, manage quality and maximize the chances of success for their projects.